The Basics of Three-Phase Electrical Systems

Electrical systems in industrial and commercial settings are very different from ones on residential premises. The former generally carry three phase power which are different conceptually and in terms of the manner in which they work. Three-phase conductors are much smaller and their over-current protections and raceways are built specifically for 3-phase circuits. In addition, it’s easier to install three phase gear compared to installing single-phase wiring.

The one challenge that you may face when you are installing three-phase electrical systems is that this power may not be provided by the utility provider at your location. Typically, 3-phase distribution lines originate from a substation and are run along the main lines after which they downsize to single phase installations for structures that require less power. But whenever, a utility service provider extends 3-phase distribution lines, they also charge higher rates to the end consumer.

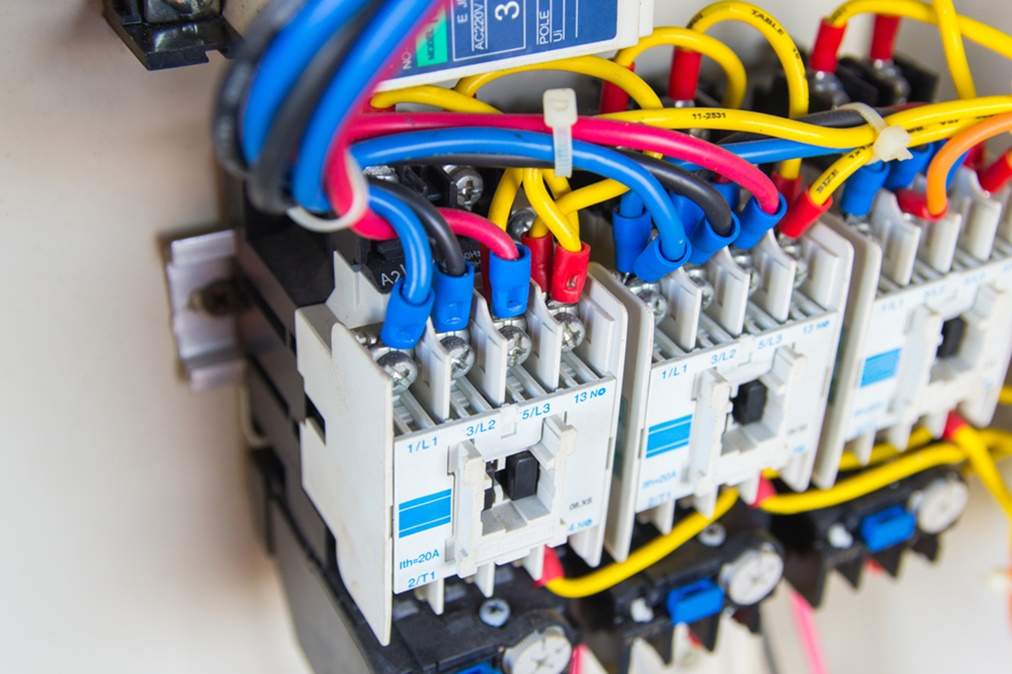

The 3-phase structure

One of the best ways to get a good sense of how this entire installation works is to drive around in suburban areas and look at the transformer arrays and power lines. This is how a typical three-phase electrical system is structured:

- 3-phase service drops consist of three different ungrounded/hot conductors

- They have a neutral that’s grounded; this terminates at a 3-lug/plus ground meter socket. From this point on they lead right up to the panels of the service entrance.

- These boxes are made up of 3 hot bus bars and neutral bars.

- It is possible to plug 3 pole breakers into box position – these pick up 3-phase power.

- A double-pole breaker has the capacity to supply a single-phase line-to-line load.

- A single-pole breaker can facilitate single-phase line-to-ground circuit.

3-phase waveform

Phase relationships of the 3V-waveforms are very evident when you do a scope trace of a standard 3-phase power system. These 3-phase power lines have an entrance panel/load centre to provide a single-phase power where required. However, an electronic/rotary phase converter is required to convert a single phase into three-phase power.

This is because the three conductors in the system carry varying current voltages that get offset by 1/3rd of the period. This also means the voltage on any one conductor peaks at 1/3rd of the cycle after any one of the other conductors and 1/3rd of a cycle before the 3rd conductor. This makes it impractical to generate the phase delay required from single-phase utility connections.

Sometimes, special procedures have to be followed to connect three-phase equipment. For instance, when you are calculating the over-current protection of any 3-phase induction/synchronous motors, specific procedures would have to be followed to provide the current at the required location and for a specific application.

The three conductors with the equipment-grounding conductor, but without any neutral will be brought right up to the motor terminals. The rotation direction might be altered by reversing any two of the3 wires. The different phases can also be balanced effectively by rolling these connections (A-B, B -C, C-A) ensuring that the direction isn’t reversed.

3-phase electrical system benefits

While designing electrical systems for manufacturing facilities or large buildings, 3-phase wiring offers numerous opportunities for capital savings. In addition, they also make maintenance easy. Large, three-phase high horsepower motors are far less expensive to purchase and operate than their single-phase counterparts. If you need three-phase power at a large scale manufacturing facility or industrial unit, you would need to hire experts to ascertain how the system can be set up at your location.

If you want to know more about our power products and services, don’t hesitate to contact us at KaRaTec Power Supply Pty. You can give us a call at 612 9808 1127. You can also fill in this contact us form.

Thanks for reading,

Karatec Power Supply Pty

612 9808 1127

Sorry, the comment form is closed at this time.